Attention

This document was last updated Nov 25 24 at 21:59

Timing Analysis

Important

The purpose of this lecture is the following.

To define timing constraints of a synchronous digital circuit

To describe timing analysis of a synchronous digital circuit

To describe the delay modeling techniques used in hardware ASIC

To describe the impact of the environment on timing analysis

To describe the use of a static timing analysis tool

Attention

The following references are relevant background to this lecture.

Chadha, R. and Bhasker, J., “Static Timing Analysis for Nanometer Designs,” Springer-Verlag, 2009. Chapter 2, 3, and 5. https://doi.org/10.1007/978-0-387-93820-2

Attention

The example discussed in this lecture is available on https://github.com/wpi-ece574-f24/ex-sta

Timing Requirements for Synchronous Circuit Operation

Correct timing in synchronous logic generally means that every flip-flop meets its basic timing requirements which include setup and hold timing (for synchronous inputs) and removal and recovery timing (for asynchronous inputs).

Setup, Hold, Recovery, Removal Time

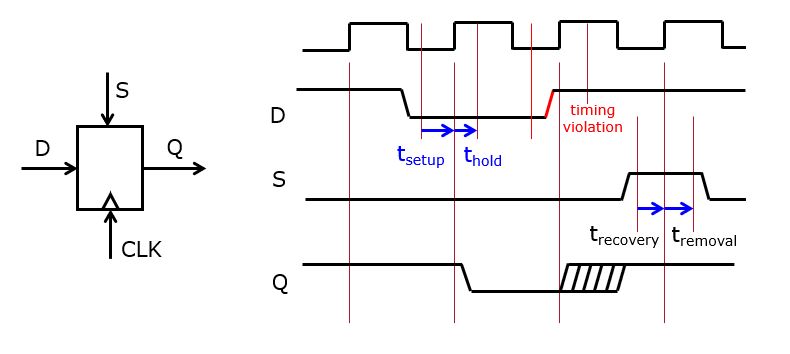

The following figure shows an edge-triggered flip-flop with an asynchronous set input. The synchronous input D is read and stored on the synchronous output Q. Four clock cycles demonstrate the meaning of setup, hold, removal and recovery.

The setup time

is the duration when a synchronous input

must be stable before a clock edge. The hold time

is the duration when a synchronous input

must be stable before a clock edge. The hold time  is the

duration when a synchronous input must be stable after a clock edge. When a

synchronous input changes during the setup/hold window, a timing

violation occurs which may leave the flip-flop in an undefined state. For

example, the input D changes just before the third clock edge, creating a

timing violation. The flip-flop may remain at 0, or it may switch to 1, or

it may switch to 1 after a long time (e.g. half a clock cycle). Physically,

any of these cases are possible as the flip-flop is in a metastable

state.

is the

duration when a synchronous input must be stable after a clock edge. When a

synchronous input changes during the setup/hold window, a timing

violation occurs which may leave the flip-flop in an undefined state. For

example, the input D changes just before the third clock edge, creating a

timing violation. The flip-flop may remain at 0, or it may switch to 1, or

it may switch to 1 after a long time (e.g. half a clock cycle). Physically,

any of these cases are possible as the flip-flop is in a metastable

state.The recovery time

is the duration that an asynchronous

that an asynchronous input must be de-asserted before a clock edge, in

order to recover normal synchronous operation. The removal time

is the duration that an asynchronous

that an asynchronous input must be de-asserted before a clock edge, in

order to recover normal synchronous operation. The removal time  is the duration that an asynchronous input must remain asserted

after a clock edge, in order to ensure the asynchronous command has effect.

Just before the fourth clock edge, the asynchronous S input is asserted,

which will force the Q output to take 1 (asserted). The S input remains

asserted longer than

is the duration that an asynchronous input must remain asserted

after a clock edge, in order to ensure the asynchronous command has effect.

Just before the fourth clock edge, the asynchronous S input is asserted,

which will force the Q output to take 1 (asserted). The S input remains

asserted longer than  after the clock edge, thus

ensuring the flip-flop returns to a stable 1.

after the clock edge, thus

ensuring the flip-flop returns to a stable 1.

Stable Operation

Let’s first establish the conditions for a synchronous circuit has correct timing. We will assume only synchronous inputs in the following examples.

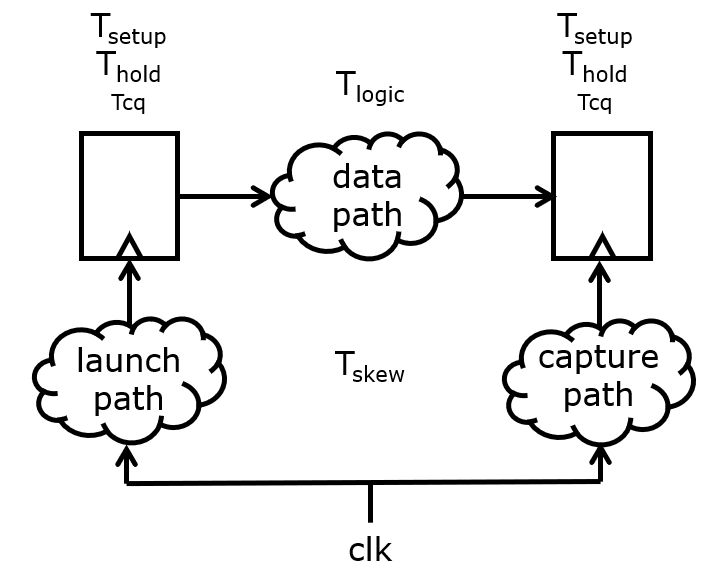

A central clock is distributed to two flip-flops with a data path in

between. The launch path is the route followed by the clock signal

(potentially including clock buffers) up until the clock input of the launch

flip-flop. The capture path is the route followed by the clock signal up

until the clock input of the capture flip-flop. The flip-flops are

characterized by setup time  , hold time

, hold time  and

clock-to-q time

and

clock-to-q time  . The latter is the time needed for the

synchronous output Q to be updated after a clock edge. The propagation

delay for the datapath

. The latter is the time needed for the

synchronous output Q to be updated after a clock edge. The propagation

delay for the datapath  is the time needed for the data

path output to be stable after its input is updated. Finally, the launch path

and capture path may result in clock skew between the two flip-flops,

meaning that the clock edge at each flip-flop does not arrive at exactly the

same moment.

is the time needed for the data

path output to be stable after its input is updated. Finally, the launch path

and capture path may result in clock skew between the two flip-flops,

meaning that the clock edge at each flip-flop does not arrive at exactly the

same moment.

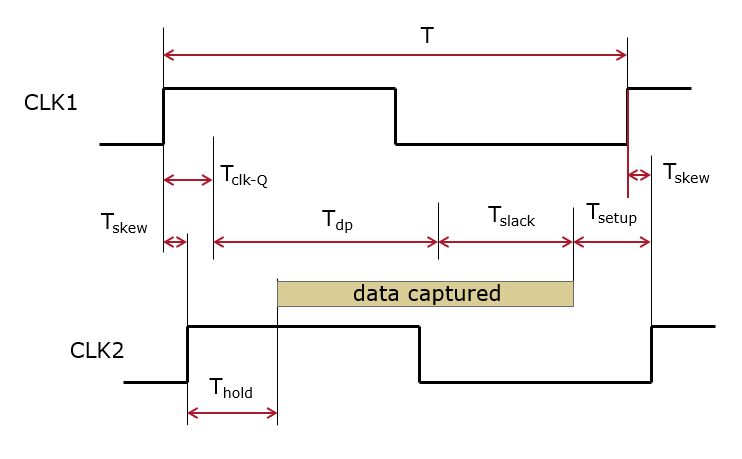

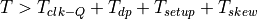

We can now derive conditions towards the

smallest possible clock period  that will ensure stable

circuit operation.

that will ensure stable

circuit operation.

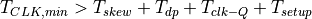

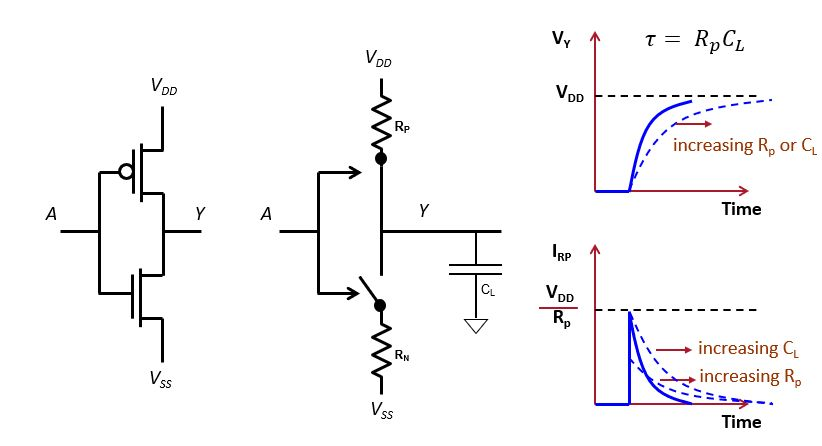

Clock Period Lower Bound

The data arriving at the capture flip flop must be stable before the capture clock edge. The slack is the margin available between the data arrival and the setup boundary at the capture flip-flop.

We want  to be positive, and therefore the following

condition must hold.

to be positive, and therefore the following

condition must hold.

Therefore, the setup time, clk-Q time and skew all potentially reduce

the time available for datapath computations. Note that in this formula,

the sign of  was not flipped when moving over from one

side of the equation to the other. That is because skew relates

to clock uncertainty. In the figure shown above, the skew from CLK1 to

CLK2 actually helps with the minimum allowed clock period. CLK2 is

delayed and therefore gives the datapath a little bit more time to

settle. However, it’s a fallacy to think that this helps our cause; simply

reversing the role of CLK2 and CLK1 in the launch path and the capture path

will make the skew work against the datapath. So, in actual timing analysis,

the skew is modeled as an uncertainty on the clock, and the uncertainty

is counted as a retricting the result.

was not flipped when moving over from one

side of the equation to the other. That is because skew relates

to clock uncertainty. In the figure shown above, the skew from CLK1 to

CLK2 actually helps with the minimum allowed clock period. CLK2 is

delayed and therefore gives the datapath a little bit more time to

settle. However, it’s a fallacy to think that this helps our cause; simply

reversing the role of CLK2 and CLK1 in the launch path and the capture path

will make the skew work against the datapath. So, in actual timing analysis,

the skew is modeled as an uncertainty on the clock, and the uncertainty

is counted as a retricting the result.

Important

The minimum clock period in a synchronous digital circuit is constrained by the setup time of the flip-flops, the clk-Q time of the flip-flops, the slowest datapath, and the clock skew between launch and capture flip-flop.

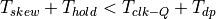

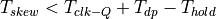

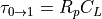

Clock Skew Upper Bound

Clock skew has to be limited and ideally, for a properly implemented clock distribution circuit, it is as close as possible to zero. However, clock skew has an upperbound too. Data arriving at the capture flip-flop cannot change in the hold time window of the capture flop-flop.

Therefore, positive skew cannot be larger than the time it takes for data to travel from the launch flip-flop through the datapath. If the skew condition is violated, than the capture flip-flop will grab data on the current clock edge rather than the next clock edge. In simulation, this appears as if the circuit skipping is a cycle, and the capture flip-flop has no effect.

When skew is negative, of course, then this condition is easy to meet. It’s also possible to look at this relation in terms of the minimum propagation delay required on a datapath for stable operation.

Important

The minimum propagation delay of a datapath is constrained by the hold time of the flip-flops, the clock skew between launch and capture flip-flop, and the clock-Q time of the flip-flops.

It’s easy to see why the ideal skew must by 0, and not negative. Assume that you have a circuit with feedback, with two flip-flops in the feedback loop. That is, register R2 is updated with a result computed from R1, and register R1 is updated with a result computed from R2. In that case, a positive skew from R1 to R2 will become a negative skew from R2 to R1, and vice versa. The ideal solution is therefore a zero skew.

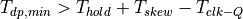

Modern hardware design for ASIC takes the skew problem specifically into account, and will generate a clock tree for a specific circuit. The following figure shows the example of a so-called H-tree which distributes a clock physically to 8 flip-flops in such a way that the skew over all flip-flops becomes close to 0. We will discuss the problem of creating a circuit to distribute the clock signal with low skew in further detail once we discuss layout generation.

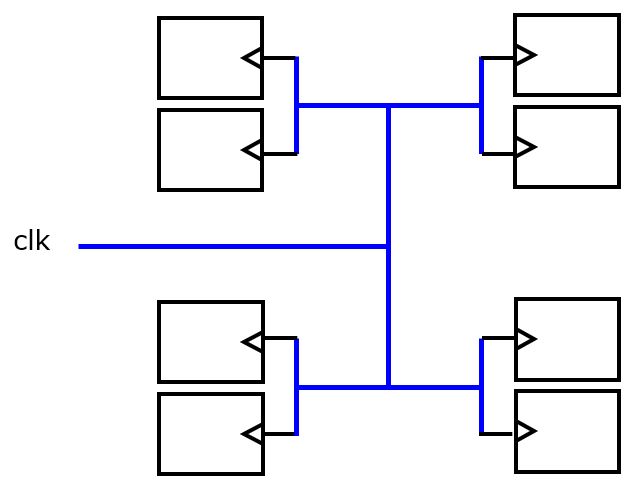

Delay Modeling

In order to verify the timing of a complex digital circuit, we must

have a way to quickly compute  . The combinational delay

of a digital circuit depends not only on the (active) logic gates that

evaluate the combinational function, but also on the (passive)

interconnect between the gates. In an ASIC layout, the latter is

defined by the placement of gates on the layout as well as the length

of the interconnect running between individual gates. The fundamental

concepts of Delay Modeling follow from the operation of CMOS logic,

such as the CMOS inverter shown next.

. The combinational delay

of a digital circuit depends not only on the (active) logic gates that

evaluate the combinational function, but also on the (passive)

interconnect between the gates. In an ASIC layout, the latter is

defined by the placement of gates on the layout as well as the length

of the interconnect running between individual gates. The fundamental

concepts of Delay Modeling follow from the operation of CMOS logic,

such as the CMOS inverter shown next.

The CMOS inverter uses a p-channel and a n-channel transistor that

will exclusively turned on, depending on the input voltage level at

the common gate A. The equivalent circuit of such a transistor is a

switch controlled by the voltage level on the common gate, as well as

an internal resistor  or

or  . The inverter gate

drives circuit interconnect and other gate inputs which are modeled -

in first order - as a loading capacitor

. The inverter gate

drives circuit interconnect and other gate inputs which are modeled -

in first order - as a loading capacitor  . Hence, when a

CMOS gate switches, it doesn’t make an immediate transition. Instead,

it charges (or discharges) a loading capacitor using an exponential

curve with a time constant propertional to

. Hence, when a

CMOS gate switches, it doesn’t make an immediate transition. Instead,

it charges (or discharges) a loading capacitor using an exponential

curve with a time constant propertional to  . Because a logic ‘1’ or a logic ‘0’ requires the voltage

to be higher (resp. lower) than a given threshold, it will therefore

take time before the output of a gate has turned from 0 to 1 or vice

versa.

. Because a logic ‘1’ or a logic ‘0’ requires the voltage

to be higher (resp. lower) than a given threshold, it will therefore

take time before the output of a gate has turned from 0 to 1 or vice

versa.

The time constant  can increase because of two factors.

can increase because of two factors.

When

or

or  increases, the gate is slower. The

resistance will increase when a weaker gate with smaller transistors

is used, i.e. when the drive strength of the gate decreases. In

addition, when a gate needs to drive a long wire, there is a

non-negligible series resistance that must be added to

increases, the gate is slower. The

resistance will increase when a weaker gate with smaller transistors

is used, i.e. when the drive strength of the gate decreases. In

addition, when a gate needs to drive a long wire, there is a

non-negligible series resistance that must be added to  or

or  to find the effective resistance.

to find the effective resistance.When

increases, the gate is slower. The loading

capacitance is determined by the type and number of gates that are

driven with this gate. The fanout is the number of gates driven,

and the higher the fanout, the slower the gate.

increases, the gate is slower. The loading

capacitance is determined by the type and number of gates that are

driven with this gate. The fanout is the number of gates driven,

and the higher the fanout, the slower the gate.

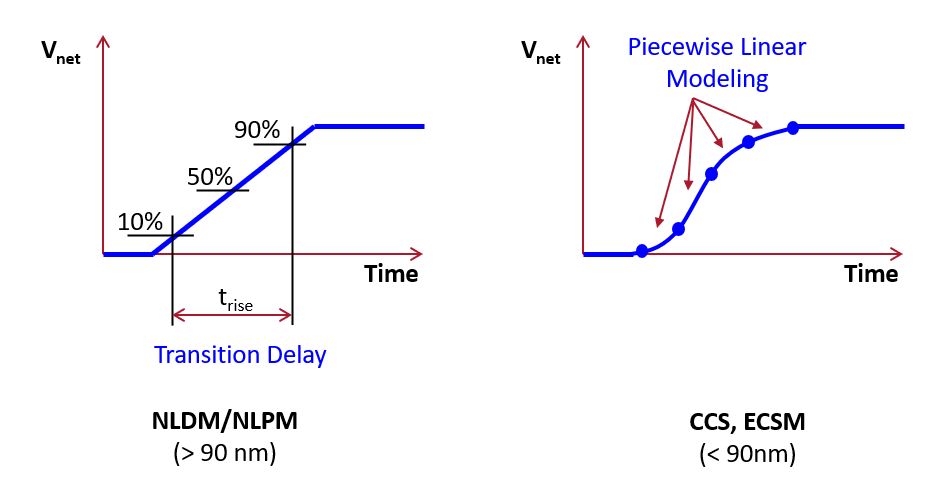

Circuit timing estimators do not directly compute exponential charging and discharging of wires. Instead, they approximate the exponential-shaped waveforms using linear or piecewise linear models. The following shows an example approximation into two popular circuit delay modeling techniques, NLDM (Non Linear Delay Modeling) and CCS (Composite Current Source).

The key difference between an NLDM and CCS model is the level of

sophistication by which the loading capacitance  of a gate

is modeled. NLDM assumes a constant loading capacitance, and is

adequate for gate technologies above 90 nm (including the SKY130 PDK

that we will be using for experiments). CCS assumes a variable loading

capacitance, and is used with gate technologies below 90 nm. In the

following discussion, we focus exclusively on NLDM modeling.

of a gate

is modeled. NLDM assumes a constant loading capacitance, and is

adequate for gate technologies above 90 nm (including the SKY130 PDK

that we will be using for experiments). CCS assumes a variable loading

capacitance, and is used with gate technologies below 90 nm. In the

following discussion, we focus exclusively on NLDM modeling.

NLDM Delay Modeling

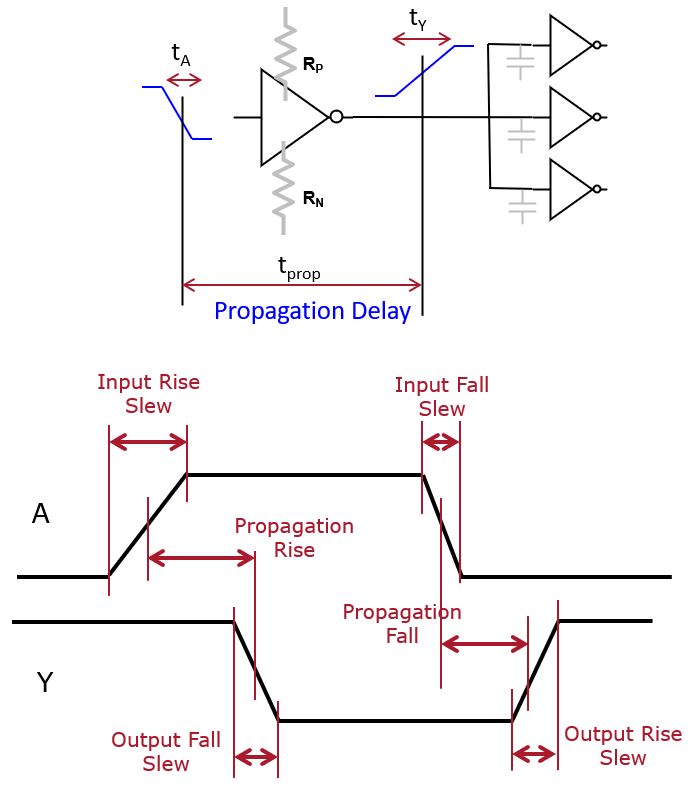

Assume an inverter circuit that drives several other gates. The NLDM model can capture delays in this circuit following the waveforms shown below the circuit.

Each transition is modeled with a given steepness or slew rate. The slew rate, which is typically measured as the time between the 10% and 90% of the signal’s transition voltage, is a first order approximation of the non-linear (exponential) charging/discharging of loading capacitance. Slew rate is modeled in terms of a transition delay. Rather than expressing the steepness of the transition, we capture the time of the transition. The propagation delay of a gate is measured as the response time between an input and a corresponding output, measured as the time between the halfway points of the transition at the input and at the output.

Each input on the network represents an equivalent loading capacitance. On a high-fanout net, many inputs are connected in parallel and thus the loading capacitance rises.

The delay computation tool now has to compute the propagation delay of every cell, as well as the transition delay for every output. The delay computation tool distinguishes rising transitions from falling transitions, and each of these transitions may take a different transition time (on a net) or a different propagation delay (on a cell).

The objective of the delay computation tool is to determine the propagation delay of every gate, as well as the transition time for every output. The propagation delay of a gate depends on the loading capacitance of the gate output, and the transition time at the input. Similarly, the transition time of an output depends on the loading capacitance of the gate output, and the transition time at the input.

When a gate has multiple inputs, there can be multiple factors for the propagation delay and the transition time of the output. The delay computation tool will consider all of them, and then select the worst possible one to reflect the propagation and transition delay of an output. The causal dependence between the input and the output of a gate in terms of delay is called a timing arc. Thus, you can imagine each gate pin as a node in a graph, and the timing arcs as the edges of that graph. Then, the delay computation of the overall circuit can be expressed in terms of finding the slowest path in that graph. Initially, most of the propagation delays and transition delays are unknown, except for those at the input. Then, the delay computation tool starts resolving all the unknowns using a per-gate lookup table, until all delays are known. Finally, the delay of the overall circuit can be determined.

Interconnect Delay Modeling

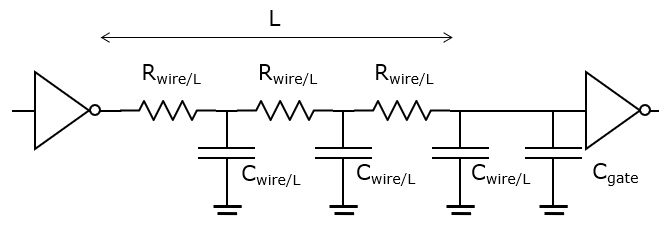

Delay is also affected by interconnect. The basic delay model of a wire accounts for its resistance and capacitance to ground, which are both proportional to the wire length.

The circuit delay through a wire modeled using an equivalent resistor

and a capacitor

and a capacitor  is given by the Elmore delay,

which sets the delay at

is given by the Elmore delay,

which sets the delay at  . To account for the distributed

(rather than lumped) nature of wire resistance and wire capacitance,

the elmore delay of a wire is rather

. To account for the distributed

(rather than lumped) nature of wire resistance and wire capacitance,

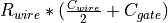

the elmore delay of a wire is rather  . Hence, the total

delay experienced by a signal edge traveling through the circuit below

is

. Hence, the total

delay experienced by a signal edge traveling through the circuit below

is  .

.

Interconnect delay is introduced in the delay estimation through two mechanisms: through a wire load model or through parasitics modeling.

Wire Load Models

In advanced technology nodes, wire delay is dominating the delay of the overall circuit. Delay computation tools deal with the delay of wires by estimating the length of the wire. The length of a wire implies an equivalent resistance and capacitance for the wire, and thus, a delay. The loading capacitance is also affecting the transition delay of the gate that drives the wire.

As long as the circuit is not physically constructed into a layout, the length of the wires and the metal layers used for each wire, is not yet known. This creates a chicken-and-egg problem, since without known the precise delays, it’s not possible to accurately size the circuit and select the proper drive strength for each gate. To get around this problem, delay computation tools (and synthesis tools) use a wire load model, an initial estimate of the resistance and capacitance of each wire based on high level circuit factors such as fanout and circuit area.

When the detailed layout of a circuit is known, the wire load model is replaced with more precise estimates for each wire in terms of resistance and capacitance. Thus, as we add more design details to the implementation, the timing estimates computed by the delay computation tool will be more precise. Typically, you will find that the timing of the circuit worsens after layout. However, it should not become so much worst that the post-layout design introduces a significant amount of timing violations. If that would occur, it could indicate that the wire load model that was chosen initially at synthesis, as not a good estimate of the actual circuit area and layout.

The Liberty Format

The delay information of a gate is stored in a specific(human-readable) format called the Liberty Format. Originally devised by Synopsys, the Liberty Format is now an open standard (http://www.opensourceliberty.org/) that is shared by other EDA vendors and cell library providers.

Attention

The Liberty files (or lib files for short) of the 130nm

high-density standard cells are stored under

/opt/skywater/libraries/sky130_fd_sc_hd/latest/timing/. There

are multiple lib files in that directory, corresponding to

different operating corners (temperature, voltage, process).

The Liberty files of CDS45 standard cells are stored under

/opt/cadence/libraries/gsclib045_all_v4.7/gsclib045/timing/. Similarly,

the different lib files in that directory correspond to different

operating corners.

For every gate in the library, the .lib file will capture the load model (the input capacitance of each gate) as well as the drive model (the gate delay and output transition delay). As an example, let’s look at the drive-strength-1 AND2 gate of the CDS45 library. The model is slightly shortened by removing information not related to timing, such as power.

cell (AND2X1) {

area : 1.368;

pin (Y) {

direction : "output";

function : "(A B)";

max_capacitance : 0.25;

timing () {

related_pin : "A";

timing_sense : positive_unate;

timing_type : combinational;

cell_rise (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.221347, 2.96281", \

"0.349336, 3.09097" \

);

}

rise_transition (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.220913, 5.14177", \

"0.22198, 5.14177" \

);

}

cell_fall (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.18609, 3.40759", \

"0.309193, 3.53088" \

);

}

fall_transition (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.259895, 6.18195", \

"0.260511, 6.18195" \

);

}

}

timing () {

related_pin : "B";

timing_sense : positive_unate;

timing_type : combinational;

cell_rise (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.230092, 2.97154", \

"0.366278, 3.10769" \

);

}

rise_transition (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.220922, 5.14177", \

"0.221819, 5.14177" \

);

}

cell_fall (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.190622, 3.41312", \

"0.316799, 3.53945" \

);

}

fall_transition (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.260612, 6.18249", \

"0.261192, 6.18251" \

);

}

}

pin (A) {

direction : "input";

max_transition : 0.28;

capacitance : 0.000205583;

rise_capacitance : 0.000205583;

rise_capacitance_range (0.000202183, 0.000210011);

fall_capacitance : 0.000164011;

fall_capacitance_range (0.000143976, 0.0001853);

}

pin (B) {

direction : "input";

max_transition : 0.28;

capacitance : 0.000208516;

rise_capacitance : 0.000208516;

rise_capacitance_range (0.000205733, 0.000210818);

fall_capacitance : 0.000186718;

fall_capacitance_range (0.000182961, 0.000191844);

}

}

This model captures information related to each pin of the gate:

A, B, and Y. The input pin models are the shortest. The

model encodes input capacitance for rising and falling transitions

separately. It also capture the capacitance range which is needed

for more advanced CCS based delay calculations. The max_transition

attribute is a constraint and represents the slowest transition that

is acceptable for the given cell characterization.

The output pin description is more sophisticated and states the

function (A B) and several timing blocks. Each timing block

encodes a timing arc, and there is a timing block for changes related

to the A input as well as changes related to the B input. The

propagation delay for the gate is encoded as the

cell_fall/cell_rise to capture delay from changes at the

corresponding input. The transition delay for the output is encoded as

fall_transition/rise_transition to capture output transition

time stemming from changes at the corresponding input. Each timing arc

has a unateness, which indicate the direction of the output

transition in function of the input transition. Positive unateness

means the output rises when the input rises, and negative unateness

means the output falls when the input rises. An output pin can also be

non-unate, when there is no logic connection between input and output

transition. For example, the Q output on a flip-flop is non-unate with

respect to the clock input signal.

The delays are encoded in lookup tables. For example, the lookup table

delay_template_2x2 is used to describe the propagation delay for a

rising output triggered from input B:

timing () {

related_pin : "B";

timing_sense : positive_unate;

timing_type : combinational;

cell_rise (delay_template_2x2) {

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.25");

values ( \

"0.230092, 2.97154", \

"0.366278, 3.10769" \

);

}

...

These encoding used for these lookup tables is stored in the .lib file

as well. For example, for delay_template_2x2 we find:

lu_table_template (delay_template_2x2) {

variable_1 : input_net_transition;

variable_2 : total_output_net_capacitance;

index_1 ("0.008, 0.28");

index_2 ("0.01, 0.3");

}

Thus, the first index of cell_rise represents the input transition

delay, and the second index of cell_rise represents the output net

capacitance. The transition delay table for cell_rise is thus

encoded as follows. (index1, index2) map to (row, column).

cell_rise

(x1) 0.01

(x2) 0.3

(y1) 0.008

(t1) 0.230092

(t2) 2.97154

(y2) 0.28

(t3) 0.366278

(t4) 3.10769

Using this table, the timing simulator can determine the right gate

propagation delay from a given capacitive load and a given input

transition. For example, if the input transition (on B) is 0.28ns

and the capacitive load at the output is 0.01 fF, then the gate

propagation delay for a rising transition is 0.366278ns. Then the

index value cannot be directly matched (to either input transition or

output capacitance), the output propagation delay will be found using

linear interpolation. For the following table:

Standard Delay Format

When additional design information becomes available (such as the fanout and type of gates used after synthesis, or the exact topology of interconnect after layout), the delay estimates of gates and wires can be refined. The standard delay format (sdf) is a data format that is used by synthesis and layout tools to provide such updated delay information. The data provided through sdf can override the delays listed in the lib file. Standard delay format can be used, for example, to initialize a gate-level timing simulation. The library provides a functional view of the gates in Verilog, and the SDF captures the delay effects of the gate-level netlist. Keep in mind that typical 4-value HDL simulation (0,1,X,Z) cannot simulate slew or transition delay.

The following is an example of an entry in an sdf file, produced by

the synthesis tool. It describes the delays of a gate g828__3680.

(CELL

(CELLTYPE "ADDFX1")

(INSTANCE g828__3680)

(DELAY

(ABSOLUTE

(PORT A (::0.000))

(PORT B (::0.000))

(PORT CI (::0.000))

(IOPATH CI CO (::0.186) (::0.172))

(IOPATH A CO (::0.200) (::0.173))

(IOPATH B CO (::0.198) (::0.173))

(IOPATH CI S (::0.286) (::0.268))

(IOPATH A S (::0.281) (::0.300))

(IOPATH B S (::0.291) (::0.294))

)

)

)

(CELLTYPE "ADDFX1")specifies the type of the cell, which is “ADDFX1” in this case.(INSTANCE g828__3680)specifies the instance name of the cell, which is “g828__3680.”(DELAY ...)defines the delay characteristics of the cell instance.(ABSOLUTE ...)indicates that the delay values provided are absolute delays.(PORT A (::0.000))specifies that the input port “A” has an absolute delay of 0.000 time units. Similar specifications hold forBandCI.(IOPATH CI CO (::0.186) (::0.172))defines an input-to-output path from “CI” to “CO” with an absolute delay of 0.186 time units and a slew (transition) delay of 0.172 time units. Similar specifications hold for other IO paths of the gate.

Static Timing Analysis

We are now ready to perform timing analysis of a complete circuit. Through delay modeling, we can annotate each gate (and possibly wire) with a given propagation delay. Now, given an arbitrarily complex circuit, we would like to verify if the setup delay constraints of flip-flops in the design are met.

First, we demonstrate how slack can be computed for any node in an arbtitrary combinational circuit. Next, we then expand this method to the static timing analysis algorithm to verify the setup/hold time of every flip-flop in the circuit, as well as the arrival time of every system output.

Actual Arrival Time in a combinational circuit

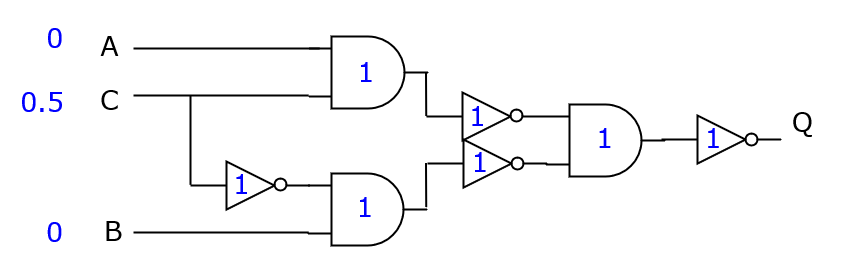

Using a straightforward graph algorithm, the propagation delay of a

network of combinational gates is computed as follows. We use the

following example as an illustration. A three-input network has a

propagation delay of 1 ns for every gate. All inputs except C are

available at the start of the clock cycle, while C is only ready

after 0.5ns. Such an input delay is a typical constraint encountered

in actual timing analysis calculations, as we will illustrate later.

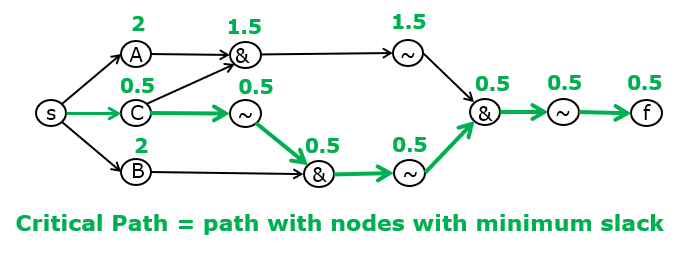

To compute the propagation delay of this circuit, we need to determine the actual arrival time (AAT), the time when output Q is available. All gates are mapped as nodes in a graph, and interconnections are mapped as edges. Inputs and outputs map to their own node. Each node is then annotated with a propagation delay, and the AAT is compute from inputs to outputs, by identifying the latest time each node output is available.

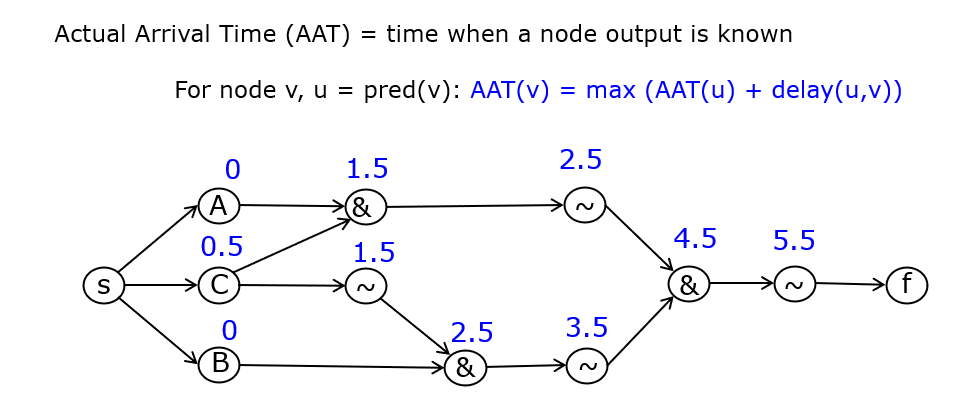

Next, we compute the required arrival time (RAT) for each node in the graph under the assumption of a given clock period. While AAT is computed from input to output, the RAT is computed from output to inputs, each time identifying the latest possible time that a node input must be ready in order to meet the overall RAT.

Finally, the slack for the circuit output, and every other node in the graph, is the difference between the RAT and the AAT. The slack must always be positive. A negative slack (for any node in the graph) indicates a timing violation and thus a circuit that does not meet its timing constraints. Also, the critical path in the graph becomes visible by highlighting all nodes with minimum slack. In the case of the example, we see that the critical path runs through input C (the slowest input) and the path that cross a maximumm overall gate delay.

Applying static timing analysis in sequential logic

The perform static timing analysis on sequential logic, the slack computation algorithm is applied to every block of combinational logic in a given module. There are four possible paths in such a circuit. These four paths enumerate the four possible paths between two kinds of inputs (module input and register output) and two kinds of output (module output and register input). The four paths are:

Combinational logic from module input to module output

Combinational logic from module input to register input

Combinational logic from register output to module output

Combinational logic from register output to register input

We compute the slack for each of these paths, and verify that each slack is positive. Static analysis tools use the term path group to mark such similar paths. In designs with multiple clocks, there can be more than four possible path groups, and the static timing analysis tool will verify to slack in every group.

Input and Output Delay

In principle, the required arrival time is equal to the chosen clock period at which the tming analysis is performed. However, there are practical arguments to verify against a tighter constraint, in particular because the module inputs and module outputs can introduce their own timing constraint.

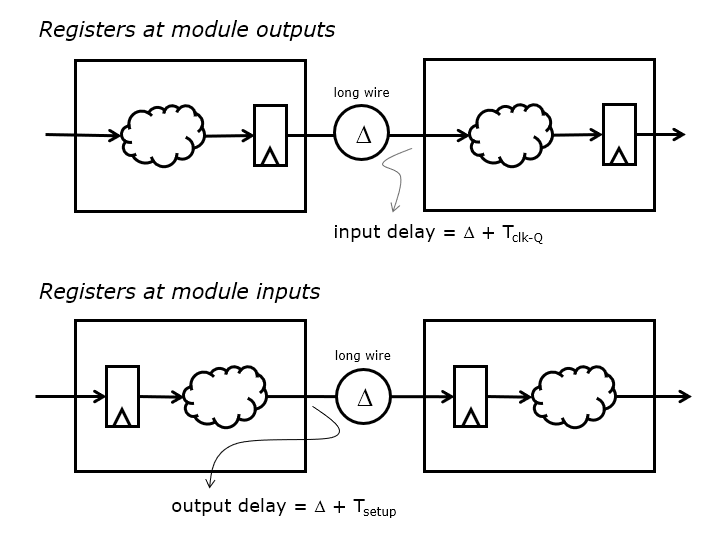

Each input can be associated with an input delay, the time after the clock edge at which the input is valid. Furthermore, each output can be associated with an output delay, the time before the clock edge at which the output must be available. The ideal input delay, as well as the ideal output delay, is zero, meaning that the entire clock period can be used for combinational computation. However, registers cannot meet that constraint. Every register has a non-zero clk-Q time, which determines the ‘input delay’ for the paths starting at a register output. Also, every register has a positive setup time, which determines the ‘output delay’ for paths ending at a register input.

In addition, external interfaces (such as the connections to memory modules) can introduce additional input/output constraints. The following example shows how one could select an input delay in an interconnect strategy that puts registers at the output. Below that, how one coudl select an output delay constraint in an interconnect strategy that puts registers at the input.

Timing Analysis with Tempus

Refer to the materials posted on Canvas (Timing Paths and SDC Constraints)

Example

We will discuss static timing analysis on the following multiply-accumulate example. Notice that this module has all four types of timing paths we discussed above: input to output, input to register, register to register and register to output.

module mac(

input logic [7:0] x1,

input logic [7:0] x2,

output logic [9:0] y,

output logic [9:0] m,

input logic reset,

input logic clk

);

logic [9:0] y_next;

logic [15:0] m16;

always_ff @(posedge clk)

if (reset)

y <= 10'b0;

else

y <= y_next;

always_comb

begin

m16 = x1 * x2;

m = m16[15:6];

y_next = y + m;

end

endmodule

First, perform RTL synthesis in the syn directory.

cd syn

make

The resulting module is implemented using 163 standard cells for a 4

ns clock constraint. The synthesis timing report states a slack of

633ps, with the critical path running from the input (x2[0]) to

the accumulator register msb (y[9]). The critical path of the

design thus includes the multiply-accumulate operation, and within

those operations the path includes the complete carry chain from LSB

to MSB.

#---------------------------------------------------------------------------------------------------------

# Timing Point Flags Arc Edge Cell Fanout Load Trans Delay Arrival Instance

# (fF) (ps) (ps) (ps) Location

#---------------------------------------------------------------------------------------------------------

x2[0] - - R (arrival) 7 2.6 0 0 0 (-,-)

mul_21_11_g847__4319/Y - A->Y F NAND2X1 2 0.8 76 61 61 (-,-)

mul_21_11_g817__5107/Y - A->Y R NOR2X1 2 1.2 84 100 160 (-,-)

mul_21_11_g806__4733/Y - B0->Y F AOI21X1 1 0.5 77 69 230 (-,-)

mul_21_11_cdnfadd_003_0__2883/S - CI->S R ADDFX1 2 0.8 46 307 537 (-,-)

mul_21_11_g802__1881/Y - A1->Y F OAI221X1 1 0.4 154 166 703 (-,-)

mul_21_11_g798__7098/Y - A1->Y R AOI22X1 2 0.8 87 157 860 (-,-)

mul_21_11_g796__8246/Y - C->Y F NOR3BX1 1 0.4 43 72 931 (-,-)

mul_21_11_g794__1705/Y - A1->Y R OAI22X1 1 0.8 100 87 1018 (-,-)

mul_21_11_g793__2802/CO - B->CO R ADDFX1 1 0.6 39 230 1249 (-,-)

mul_21_11_g792__1617/CO - CI->CO R ADDFX1 1 0.6 39 186 1435 (-,-)

mul_21_11_g791__3680/CO - CI->CO R ADDFX1 1 0.6 39 186 1621 (-,-)

mul_21_11_g790__6783/CO - CI->CO R ADDFX1 1 0.6 39 186 1807 (-,-)

mul_21_11_g789__5526/CO - CI->CO R ADDFX1 1 0.6 39 186 1993 (-,-)

mul_21_11_g788__8428/CO - CI->CO R ADDFX1 1 0.6 39 186 2179 (-,-)

mul_21_11_g787__4319/CO - CI->CO R ADDFX1 1 0.6 39 186 2365 (-,-)

mul_21_11_g786__6260/CO - CI->CO R ADDFX1 1 0.6 39 186 2551 (-,-)

mul_21_11_g785__5107/S - CI->S F ADDFX1 2 0.7 45 271 2822 (-,-)

g707__4319/CO - B->CO F ADDFX1 1 0.4 37 172 2994 (-,-)

g705__5107/Y - B->Y R XNOR2X1 1 0.2 22 163 3157 (-,-)

g703__2398/Y - AN->Y R NOR2BX1 1 0.3 39 86 3243 (-,-)

y_reg[9]/D <<< - R DFFHQX1 1 - - 0 3243 (-,-)

#---------------------------------------------------------------------------------------------------------

For a better insight into the timing behavior of the module, we run

the timing analysis again under sta.

cd ta

make

The static timing analysis makes use of the following timing analysis script. The following indicate particular activities.

The script inputs are the gate-level netlist, the standard cell library, and the constraint file as well as the SDF generated by the synthesis. Thus, the STA results from this run may not be identical to those produced by the synthesis because the constraints/sdf is not identical.

The script produces three files. The first file,

late.rptshows the three longest paths in the system as they pertain to register setup tests. The second file,early.rptshows the three longest paths in the system as they pertain to register hold checks. The third file,allpaths.rpt, shows a summary of the longest path starting at each input, output, register input and register output. This third file gives an understanding how the worst case path (fromx2[0]toy[9]) relates to other slow paths in the module.The script uses Tempus commands; consult the Tempus command reference manual (on Cadence support) for variations of these commands. Some of them, such as

report_timing, support many variations and are worth exploring.

read_lib /opt/cadence/libraries/gsclib045_all_v4.7/gsclib045/timing/slow_vdd1v0_basicCells.lib

read_verilog ../syn/outputs/mac_netlist.v

set_top_module mac

read_sdc ../syn/outputs/mac_constraints.sdc

read_sdf ../syn/outputs/mac_delays.sdf

report_timing -late -max_paths 3 > late.rpt

report_timing -early -max_paths 3 > early.rpt

report_timing -from [all_inputs] -to [all_outputs] -max_paths 12 -path_type summary > allpaths.rpt

report_timing -from [all_inputs] -to [all_registers] -max_paths 12 -path_type summary >> allpaths.rpt

report_timing -from [all_registers] -to [all_registers] -max_paths 12 -path_type summary >> allpaths.rpt

report_timing -from [all_registers] -to [all_outputs] -max_paths 12 -path_type summary >> allpaths.rpt

exit

First, let’s look at the worst path from late.rpt. That path turns

out to be worse than the path reported by the synthesis tool although

it’s quite close. The differences are cause by the use of SDF.

Path 1: MET Setup Check with Pin y_reg[9]/CK

Endpoint: y_reg[9]/D (^) checked with leading edge of 'clk'

Beginpoint: x2[0] (^) triggered by leading edge of 'clk'

Path Groups: {clk}

Other End Arrival Time 0.000

- Setup 0.124

+ Phase Shift 4.000

= Required Time 3.876

- Arrival Time 3.291

= Slack Time 0.585

Clock Rise Edge 0.000

+ Input Delay 0.000

= Beginpoint Arrival Time 0.000

-------------------------------------------------------------------------------

Instance Arc Cell Delay Arrival Required

Time Time

-------------------------------------------------------------------------------

- x2[0] ^ - - 0.000 0.585

mul_21_11_g847__4319 A ^ -> Y v NAND2X1 0.061 0.061 0.646

mul_21_11_g817__5107 A v -> Y ^ NOR2X1 0.100 0.161 0.746

mul_21_11_g806__4733 B0 ^ -> Y v AOI21X1 0.069 0.230 0.815

mul_21_11_cdnfadd_003_0__2883 CI v -> S ^ ADDFX1 0.307 0.537 1.122

mul_21_11_g802__1881 A1 ^ -> Y v OAI221X1 0.166 0.703 1.288

mul_21_11_g798__7098 A1 v -> Y ^ AOI22X1 0.157 0.860 1.445

mul_21_11_g796__8246 C ^ -> Y v NOR3BX1 0.072 0.932 1.517

mul_21_11_g794__1705 A1 v -> Y ^ OAI22X1 0.087 1.019 1.604

mul_21_11_g793__2802 B ^ -> CO ^ ADDFX1 0.230 1.249 1.834

mul_21_11_g792__1617 CI ^ -> CO ^ ADDFX1 0.186 1.435 2.020

mul_21_11_g791__3680 CI ^ -> S ^ ADDFX1 0.290 1.725 2.310

g725__1881 B ^ -> CO ^ ADDFX1 0.203 1.928 2.513

g722__7098 CI ^ -> CO ^ ADDFX1 0.186 2.114 2.699

g719__5122 CI ^ -> CO ^ ADDFX1 0.186 2.300 2.885

g716__2802 CI ^ -> CO ^ ADDFX1 0.186 2.486 3.071

g713__3680 CI ^ -> CO ^ ADDFX1 0.186 2.672 3.257

g710__5526 CI ^ -> CO ^ ADDFX1 0.186 2.858 3.443

g707__4319 CI ^ -> CO ^ ADDFX1 0.184 3.042 3.627

g705__5107 B ^ -> Y ^ XNOR2X1 0.163 3.205 3.790

g703__2398 AN ^ -> Y ^ NOR2BX1 0.086 3.291 3.876

y_reg[9] D ^ DFFHQX1 0.000 3.291 3.876

-------------------------------------------------------------------------------

Next, look at the fastest path with respect to hold time in

early.rpt. This path runs from reset to a register input. The

overall module uses syncrhonous reset, so this reset signal is a

simple system input. Because the system constraint uses an input delay

of 0, the STA assumes that reset can change directly after the upgoing

clock edge, thereby potentially affecting y_reg[7]. However, as

the report shows, there is no hold time violation.

Path 1: MET Hold Check with Pin y_reg[7]/CK

Endpoint: y_reg[7]/D (v) checked with leading edge of 'clk'

Beginpoint: reset (^) triggered by leading edge of 'clk'

Path Groups: {clk}

Other End Arrival Time 0.000

+ Hold 0.006

+ Phase Shift 0.000

= Required Time 0.006

Arrival Time 0.020

Slack Time 0.014

Clock Rise Edge 0.000

+ Input Delay 0.000

= Beginpoint Arrival Time 0.000

---------------------------------------------------------

Instance Arc Cell Delay Arrival Required

Time Time

---------------------------------------------------------

- reset ^ - - 0.000 -0.014

g709__8428 B ^ -> Y v NOR2BX1 0.020 0.020 0.006

y_reg[7] D v DFFHQX1 0.000 0.020 0.006

---------------------------------------------------------

Finally, look at the path summary of the overall module in

allpath.rpt. This results show that the slack is minimal indeed

for the input-to-register path. Note also the significant variation

of the slack within a path group (e.g. input-to-register) as well as

between apth groups. In this case, the x2[0 to y_reg[9] path

is so much longer than anything else, that it dominates the

delay. Hence, any timing optimization on this module should start by

considering that specific part of the design. However, in other case,

other parts of the design may be equally slow so that the critical

path tends to jump around as soon as we start making small

changes/optimzations. The use of STA (and tempus, in particular) can

help us understand how design changes can affect the critical path. In

the quiz, you will explore this aspect further.

# Command: report_timing -from [all_inputs] -to [all_outputs] -max_paths 12 -path_type summary > allpaths.rpt

--------------------------------------------------------------------------------------------------------------------------------------

Path No. Begin Point End Point Slack Arrival Required Phase Other Phase

--------------------------------------------------------------------------------------------------------------------------------------

1 x2[0] ^ m[8] ^ 1.159 2.841 4.000 clk(D)(P) * clk(C)(P)

2 x2[0] ^ m[9] ^ 1.265 2.735 4.000 clk(D)(P) * clk(C)(P)

3 x2[0] ^ m[7] ^ 1.345 2.655 4.000 clk(D)(P) * clk(C)(P)

4 x2[0] ^ m[6] ^ 1.531 2.469 4.000 clk(D)(P) * clk(C)(P)

5 x2[0] ^ m[5] ^ 1.717 2.283 4.000 clk(D)(P) * clk(C)(P)

6 x2[0] ^ m[4] ^ 1.903 2.097 4.000 clk(D)(P) * clk(C)(P)

7 x2[0] ^ m[3] ^ 2.089 1.911 4.000 clk(D)(P) * clk(C)(P)

8 x2[0] ^ m[2] ^ 2.275 1.725 4.000 clk(D)(P) * clk(C)(P)

9 x2[0] ^ m[1] ^ 2.463 1.537 4.000 clk(D)(P) * clk(C)(P)

10 x2[3] ^ m[0] v 2.647 1.353 4.000 clk(D)(P) * clk(C)(P)

--------------------------------------------------------------------------------------------------------------------------------------

# Command: report_timing -from [all_inputs] -to [all_registers] -max_paths 12 -path_type summary >> allpaths.rpt

--------------------------------------------------------------------------------------------------------------------------------------

Path No. Begin Point End Point Slack Arrival Required Phase Other Phase

--------------------------------------------------------------------------------------------------------------------------------------

1 x2[0] ^ y_reg[9]/D ^ 0.585 3.291 3.876 clk(D)(P) * clk(C)(P)

2 x2[0] ^ y_reg[8]/D ^ 0.643 3.233 3.876 clk(D)(P) * clk(C)(P)

3 x2[0] ^ y_reg[7]/D ^ 0.829 3.047 3.876 clk(D)(P) * clk(C)(P)

4 x2[0] ^ y_reg[6]/D ^ 1.015 2.861 3.876 clk(D)(P) * clk(C)(P)

5 x2[0] ^ y_reg[5]/D ^ 1.201 2.675 3.876 clk(D)(P) * clk(C)(P)

6 x2[0] ^ y_reg[4]/D ^ 1.387 2.489 3.876 clk(D)(P) * clk(C)(P)

7 x2[0] ^ y_reg[3]/D ^ 1.573 2.303 3.876 clk(D)(P) * clk(C)(P)

8 x2[0] ^ y_reg[2]/D ^ 1.767 2.109 3.876 clk(D)(P) * clk(C)(P)

9 x2[0] ^ y_reg[1]/D ^ 1.964 1.912 3.876 clk(D)(P) * clk(C)(P)

10 x2[3] ^ y_reg[0]/D ^ 2.348 1.511 3.859 clk(D)(P) * clk(C)(P)

--------------------------------------------------------------------------------------------------------------------------------------

# Command: report_timing -from [all_registers] -to [all_registers] -max_paths 12 -path_type summary >> allpaths.rpt

--------------------------------------------------------------------------------------------------------------------------------------

Path No. Begin Point End Point Slack Arrival Required Phase Other Phase

--------------------------------------------------------------------------------------------------------------------------------------

1 y_reg[0]/Q ^ y_reg[9]/D ^ 1.821 2.055 3.876 clk(D)(P) * clk(C)(P)

2 y_reg[0]/Q ^ y_reg[8]/D ^ 1.879 1.997 3.876 clk(D)(P) * clk(C)(P)

3 y_reg[0]/Q ^ y_reg[7]/D ^ 2.065 1.811 3.876 clk(D)(P) * clk(C)(P)

4 y_reg[0]/Q ^ y_reg[6]/D ^ 2.251 1.625 3.876 clk(D)(P) * clk(C)(P)

5 y_reg[0]/Q ^ y_reg[5]/D ^ 2.437 1.439 3.876 clk(D)(P) * clk(C)(P)

6 y_reg[0]/Q ^ y_reg[4]/D ^ 2.623 1.253 3.876 clk(D)(P) * clk(C)(P)

7 y_reg[0]/Q ^ y_reg[3]/D ^ 2.809 1.067 3.876 clk(D)(P) * clk(C)(P)

8 y_reg[0]/Q ^ y_reg[2]/D ^ 2.995 0.881 3.876 clk(D)(P) * clk(C)(P)

9 y_reg[0]/Q ^ y_reg[1]/D ^ 3.187 0.689 3.876 clk(D)(P) * clk(C)(P)

10 y_reg[0]/Q v y_reg[0]/D ^ 3.506 0.353 3.859 clk(D)(P) * clk(C)(P)

--------------------------------------------------------------------------------------------------------------------------------------

# Command: report_timing -from [all_registers] -to [all_outputs] -max_paths 12 -path_type summary >> allpaths.rpt

--------------------------------------------------------------------------------------------------------------------------------------

Path No. Begin Point End Point Slack Arrival Required Phase Other Phase

--------------------------------------------------------------------------------------------------------------------------------------

1 y_reg[1]/Q v y[1] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

2 y_reg[2]/Q v y[2] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

3 y_reg[3]/Q v y[3] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

4 y_reg[4]/Q v y[4] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

5 y_reg[5]/Q v y[5] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

6 y_reg[6]/Q v y[6] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

7 y_reg[7]/Q v y[7] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

8 y_reg[8]/Q v y[8] v 3.798 0.202 4.000 clk(D)(P) * clk(C)(P)

9 y_reg[0]/Q v y[0] v 3.804 0.196 4.000 clk(D)(P) * clk(C)(P)

10 y_reg[9]/Q v y[9] v 3.806 0.194 4.000 clk(D)(P) * clk(C)(P)

--------------------------------------------------------------------------------------------------------------------------------------